Category: Uncategorized

A joint venture between FORBES MARSHALL, India, and VYNCKE, Belgium

Walhalla for Belgian companies in India: “Growth in India will be greater than in China”

Vyncke acquires swedish combustion specialists petro bio

PetroBio is a family-owned company, based in Gotenburg, Sweden. They provide burner technology and deliver boiler rebuilds or new boiler plants for custom made purposes. They specialize in designing burners for all types of solid, liquid and gaseous fuels in the 2 MW to 100 MWth range. Their expertize, however, lies in the development of a specific burner used for wood pellets and wood powder combustion.

In February 2018, Vyncke acquired PetroBio in the capacity of an independent sister company within the Vyncke – A Family of Companies – holding group.

The vynckeneers have a new nest in mataró – catalunya

The year 2019 marked an extension of the VYNCKE family settlements in the country of Spain.

LSolé is a family-owned company with a 50-year track record of supplying small size biomass projects in Spain, France and Central America. After a challenging phase, LSolé reorganized itself under the leadership of Daniel Solé and Joan Ribas to form current day, BaW Energy. With a solid product, know-how and ambition goals in mind, the company’s value system and vision perfectly sync with that of VYNCKE’s.

Under the brand VYNCKE, the “LSolé Series” will consist of a team with an aim to realize the best quality cost ratio biomass boilers in the range of 1 to 10MW. They will stay focused in this capacity range and offer competitive solutions for America, Europe and Africa.

Located in Mataró, Spain and led by Daniel Solé and Joan Ribas, the incorporation of BaW Energy into the VYNCKE ecosystem strengthens VYNCKE’s market position in Latin-America.

Keep the fire burning

As the COVID-19 virus continues to spread rapidly, many governments are undertaking drastic measures to fight back. As a global company, we find it our responsibility to play our part during this period of crisis and contribute in reducing the impact of the current pandemic. As always, our aim will be to protect our employees & their families, our customers and our suppliers, as much as possible.

To keep them healthy and safe, we have adapted our services to suit the need of the hour:

- Our employees work where possible from home and we have foreseen a minimum occupancy at our settlements, around the globe.

- Physical meetings with customers and suppliers have been postponed or organized via telephone or video calls.

- Non-essential traveling is postponed.

Despite the change in our routine, we will do our utmost in providing our customers with the service levels that they are used to and that are expected from us. Our production also continues until further notice and we evaluate the situation on our construction sites on a day-to-day basis.

With a sharp decline in the new cases of infected patients in China, we see how the country rebounds. The news that the life of our Vynckeneers in China is gradually getting back to normal, brings us a lot of optimism.

It will keep us, the Vynckeneers, going.

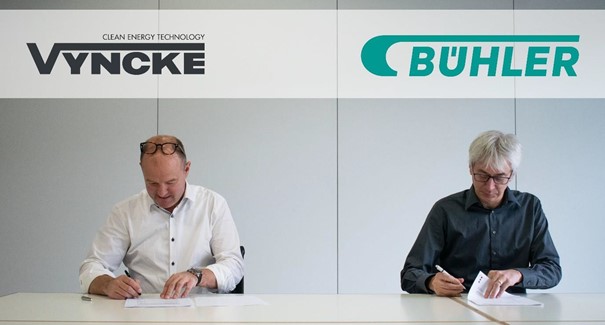

Vyncke forms a strategic partnership with bühler

The global leading food technology provider, Bühler signs a partnership contract with VYNCKE to offer integrated solutions wherein biomass side streams are transformed into clean process energy. While reducing the customers’ carbon footprint, this alliance will enable industries to reduce their dependency on fossil fuels and achieve sustainability.

Uzwil – Switzerland, March 4, 2021 – Bühler Group and Vyncke form a strategic partnership to offer integrated solutions with which biomass side stream products are transformed into clean process energy while reducing the customers’ carbon footprint. The dependency on fossil fuels – and with this, CO2 emissions– can decrease from 20%-100%, depending on the raw material and side stream products. This means that in some cases, food plants can become fully carbon neutral. The first focus of the partnership is the segments of cocoa, oat, and malt processing. “This partnership is a key element in our strategy to massively reduce CO2 in the value chains of our customers,” says Johannes Wick, CEO of Bühler Grains & Food. “Many industries rely on our solutions to reduce their fossil fuel consumption. With Bühler, we now aim to also become the standard to reduce the CO2 footprint of the food industry,” says Peter Vyncke, owner of Vyncke. “Together, Bühler and Vyncke can now offer integrated and optimized solutions where economic and ecological benefits go hand in hand.”

Biomass by-products are generated in almost all food processes. Typical examples are the processing of grains, rice, corn, and cocoa. Today, by-products are often either used for animal feed or simply disposed of. From biomass by-products, food manufacturers can also produce a climate-neutral form of energy. Like the combustion of fossil fuels, the use of biomass energy helps controlling greenhouse gas emissions as the only fraction released corresponds to what the plants previously took from the atmosphere during their growth, which is less than transporting the side stream products to a place where they would be used for feed or disposal. This creates a neutral CO2 cycle. With new equipment, digital services and retrofit offerings, Bühler already made strong progress in making its solutions more energy efficient. “By adding Vyncke’s energy recovery processes to our portfolio, we can offer our customers low- to zero-carbon food solutions,” says Johannes Wick.

Belgian technology supplier Vyncke specializes in energy production from a wide range of biomass byproducts, including industrial or municipal wastes. The range of biomass-based fuels available for energy production is broad; from agricultural and wood residues to sludges from industrial processes, recycled wood, and specially grown energy crops. Vyncke designs and builds green and clean energy systems that combust biomass and waste to produce thermal process energy from 1-100 megawatt hours – Mwh and electrical energy from 0.5-15 megawatt electrical – Mwe.

Outside of energy-intensive industries, most companies have tended to view energy procurement as a cost to be managed rather than a strategic area in the value chain. Yet today, energy is becoming one of the most important levers for business success. With their cooperation, Bühler Group and Vyncke are addressing this issue to develop solutions for more sustainable food production – with holistic process chains in which energy recovery is integrated so that external energy consumption and energy costs can be reduced. This not only contributes to greater sustainability, but also opens competitive advantages for food producers through greater energy efficiency.

“Today, we are far from exploiting the full potential of recovering energy from side stream products. Our goal is to reduce the energy consumption of a food plant by up to 70%. The beauty of our solutions is that sustainability and economic criteria go hand in hand. Today, we are already enabling our customers to reduce emissions by 2.5 million tons of CO2 annually. By partnering with Bühler, we can further improve and scale these solutions in an integrated approach to create a much larger positive impact,” says Peter Vyncke.

One particularly important joint project will be the expansion of a malt production plant for Bühler’s long-time business partner, Malteria Oriental S.A. in Montevideo, Uruguay. Malteria Oriental S.A. belongs to the Grupo Petrópolis, one of Brazil’s largest beer producers. Their brewing business requires more malt, as beer consumption in South America has grown steadily in recent years.

In malt houses, the thermal energy consumption for drying malt is enormous. In the project, Vyncke will be responsible for recovering thermal energy from biomass, which is a by-product of malt production. Through an on-site energy audit, Vyncke developed a set-up to reduce the size of the energy system by 30%, creating savings in the total investment as well as the operational costs. Vyncke will build a turnkey 20-megawatt superheated water boiler with dual combustion systems which will burn internal barley husks and plant rejects, completed by externally sourced wood chips. This will save 35,000 tons of CO2 emissions each year compared to standard operational practices in Uruguay.

The new malt house is designed for a batch size of 260 tons of barley and has an annual capacity of 77,000 tons of malt. Commissioning and production are scheduled for March 2022.

“By working closely together, we aim to execute projects with less coordination effort for our customer. Our joint innovative strength will drive us into the future and our customers will have ever better and more efficient solutions at their disposal,” says Johannes Wick.

Both Vyncke and Bühler have set the goal of reducing energy consumption in all new food plants by at least 50% by 2025. Together, both partners want to create the possibility of making malting plants CO2 neutral. The project in Uruguay is just the beginning. In the future, both partners intend to coordinate their solutions technologically in a targeted manner.

You can read more in the article published by Bühler. Click here!

Vyncke is ready for the future!

Peter and Dieter VYNCKE are ensuring the continuity of the family business. They are developing the management team and will no longer assume an operational role themselves. In future, together with their father Dirk, the brothers will focus on the expansion of the industrial holding company above VYNCKE. They want to prepare the company for the next generation and develop the family business into a ‘family of businesses’.

VYNCKE became a fourth-generation family business when Peter VYNCKE took over as CEO, in 2002. In 2017, brother Dieter VYNCKE also took the helm as co-CEO. The brothers’ dream – to make VYNKCE a benchmark worldwide – has already been realized to a great extent. “We have achieved the desired level of excellence. It is now time for the next step. Familiar faces will appear in operational roles, and we will focus on the holding company above Vyncke”, explain Peter and Dieter VYNCKE.

Familiar faces in new positions

Going forward, three familiar faces from within the company take over new operational roles. Stefaan LAUWERS, COO of the enterprise since 2017, takes over the day-to-day management and becomes CEO. He has already been heading up the company de facto together with the management for some time. Stefaan is followed by Kenny MASSCHELEIN, who has been in charge for a number of operational divisions in his 18 years with Vyncke. He takes over the position of COO. The third familiar face is that of Diederik DUMON. He combines his role as CFO of Vyncke, with that of CFO of the holding company. The fact that the brothers will no longer assume any operational roles, will not present any problems. “In practice, we have already taken on less of an operational position for a number of years now and it works brilliantly. For this reason, this is an entirely natural evolution, and we have every confidence in the strong management team.” Explain the brothers.

Stefaan LAUWERS also looks to the future with confidence: “The issue of waste is becoming more challenging, and our clients are also justifiably looking for more sustainable solutions for their energy requirements. VYNCKE offers a wide variety of solutions and will continue to focus on this area in the future. In addition to building new energy plants, the expansion of our maintenance services and operational support is high on the agenda. The latest digital tools underpin this ambition.”

VYNCKE means to become a proactive industrial group

Peter and Dieter will not loosen their hold on the family business but will instead enable the family holding company to grow into a proactive industrial group. “With the help of the holding company, we are going to make a ‘family of businesses’ out of our ‘family business’, with a view to a sustainable future,” they clarified regarding their role. They will act as company ambassadors together with their father Dirk, and keep in contact with customers, suppliers and the wider community.

All VYNCKE corporations and joint ventures will be grouped together within the holding company. The family industrial holding company is comprised, in part, of the VYNCKE group. The family also participates in four joint ventures, namely PETROBIO AB in Sweden (75%), CALLENS VYNCKE in Flanders (50%), TRASMEC SRL in Italy (10%), and FORBES VYNCKE PVT LTB in India (50%). The holding company also includes the real estate arm of the business, Vinkenest NV.

The ‘family of businesses’ mission remains: ‘Energize the Industry’, renewable energy for the industry, whether that be biomass, waste, sun, wind, battery power or future innovations. “In our new role, we will go in pursuit of new opportunities for the family, in the form of acquisitions, new ventures or extra partnerships. In order to do this, we will concentrate on business development and networking,” states Dieter VYNCKE. For this reason, Peter VYNCKE relocates to Singapore to be closer to the Asian market.